Why use ePower-Board?

ePower-Board is a special device dedicated to the kinetic energy recovery processing of regenerative braking when eRob rotary actuator works under high rotational speed and heavy load, so as to avoid the power voltage spike caused by the regenerative kinetic energy feedback, which may cause the error reports of too high bus voltage and may further cause the shutdown of rotary actuator.

Function of ePower-Board:

The function of ePower-Board is that when the circuit loop is in kinetic energy recovery processing, the excess energy can be dissipated through the resistance, thereby avoiding the power supply voltage spike in the process of the kinetic energy feedback. However, the ePower-Board cannot be connected to the circuit for a long time, otherwise more heat will be generated continually, resulting in device damage, circuit failure or unnecessary current consumption.

ePower-Board Parameters:

Size: 75*80*22.5(mm)

Weight: 66.5(g)

Input voltage: <50(VDC)

Regenerative braking voltage at start: 51(VDC)

Regenerative braking voltage at stop: 50(VDC)

Power of brake resistor: 50(W)

Resistance of brake resistor: 5(Ω)

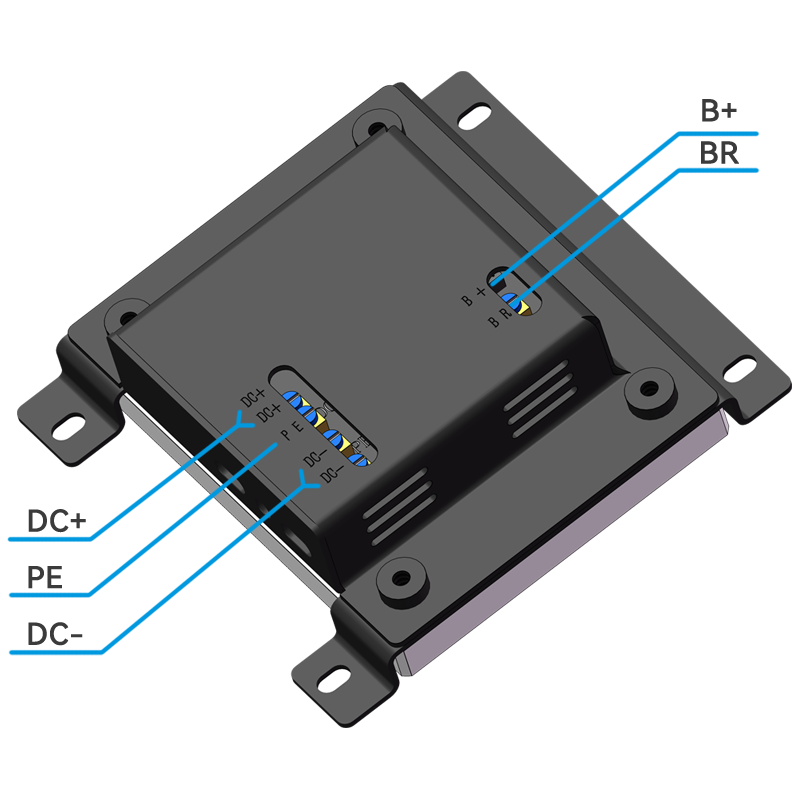

Definition of electrical interface:

| Pin | Terminal sign | Terminal function | Terminal specification |

| 1 | DC+ | Connect to the positive pole of 48VDC power |

Frame-type,Crimped terminal, |

| 2 | PE | Connect to the housing EGND | |

| 3 | DC- | Connect to the negative pole of 48VDC power | |

| 4 | BR | Connect to the brake resistor | |

| 5 | B+ |

Instruction:

The wiring diagram of 48V DC power, ePower-Board and rotary actuator is shown as follow.

The power wiring methods of rotary actuator, please refer to Section 7.1 Power wiring methods introduction in eRob Rotary Actuator User Manual.

Refer to the following table for the recommended specifications of DC48V power, electrolytic capacitor C and brake resistor R for each model of eRob rotary actuator.

Specification for each rotary actuator:

| Model | DC Power Supply Spec. | Brake Resistor Spec. | Electrolytic Capacitor Spec. |

| eRob70 | 100W、48VDC | 50W、5Ω | 12000μF、60V |

| eRob80 | 200W、48VDC | 50W、5Ω | 12000μF、60V |

| eRob90 | 400W、48VDC | 50W、5Ω | 36000μF、60V |

| eRob110 | 800W、48VDC | 300W、5Ω | 96000μF、60V |

| eRob142 | 1200W、48VDC | 300W、5Ω | 96000μF、60V |

| eRob170 | 1200W、48VDC | 300W、5Ω | 96000μF、60V |

Recommended specifications for each robot arm:

| Arm Model | DC Power Spec. | Brake Resistor Spec. | Electrolytic Capacitor Spec. |

| 3kg Robot Arm | 400W、48VDC | 50W、5Ω | 12000μF、60V |

| 5kg Robot Arm | 800W、48VDC | 100W、5Ω | 96000μF、60V |

| 10kg Robot Arm | 1500W、48VDC | 300W、5Ω | 96000μF、60V |

| 20kg Robot Arm | 3000W、48VDC | 300W、5Ω | 96000μF、60V |

Note: If the air switch is connected before the input of the rotary actuator power interface, a buffer electrolytic capacitor must be connected after the air switch (reference specification: 1000uF, 100V).