Absolute Encoder for Motor

Multiturn Absolute

Absolute Encoder for Motor

Multiturn Absolute

*

Under no-load conditions and an ambient temperature of 25°C,when the output shaft speed is 0,measurement values for different modules may vary. These data are for reference only.

**

For collaborative robots with a 20kg load,under normal operating conditions, the surface temperature of the sixth axis may vary between different modules and environments.These values are for reference only.

***

Based on the lifespan calculation formula

.

taking the fourth axis of a 20kg collaborative robot as an example:

Due to the reduced weight of the last three eRob90 joints,the load on the fourth axis decreases, thereby enhancing its lifespan:

The lifespan of the eRob 90I V6 can be increased by 13.2%.

Reference: HarmonicDrive Reducer Catalog, formula 012-1, PP.12.

More suitable for humanoid robots, bionic robots, and collaborative robots

| Similarities Between Different Versions | Installation Methods | Same,Compatible | |||||||||

| Hollow Bore Diameter | 18mm | ||||||||||

| Precision | Repeatability/Absolute Accuracy: ±7/±15 arc sec or ±10/±25 arc sec* | ||||||||||

| Electrical Interface | Communication Protocol:EtherCAT/CANopen/Modbus,Output-side Encoder Resolution:19/20Bit | ||||||||||

| Strain wave gear-ratio | 20-50 | 20-80 | 20-100 | 20-120 | |||||||

| Peak torque for start and stop(Nm) | 73 | 96 | 107 | 113 | |||||||

| Permissible max.value at average load torque(Nm) | 44 | 61 | 64 | 64 | |||||||

| Rated torque(Nm) | 33 | 44 | 52 | 52 | |||||||

| Permissible maximum momentary torque(Nm) | 127 | 165 | 191 | 191 | |||||||

| Max. output rotational speed(RPM) | 60 | 37.5 | 30 | 25 | |||||||

| Power Input Voltage(V) | |||||||||||

| 48V(±10%) Please make sure to read "Comparison of Switching Power Supply and ePower" and the "eRob Rotary Actuator User Manual" Chapter 3, for clear instructions on powering the eRob module.

|

|||||||||||

| Version | V3 | V6 | |||||||||

| Motor power(W) | 300 | 314 | |||||||||

| SWG Output Side Inertia(g-mm2) | 297466 | 273391 | |||||||||

| SWG Output Side Mass(kg) | 0.36 | 0.321 | |||||||||

| Without Brake | SWG Input Side Inertia(g∙mm²) | 139067 | 95791 | ||||||||

| SWG Input Side Mass(kg) | 0.41 | 0.257 | |||||||||

| OD * Length(mm) | Φ90x98.9 | Φ90x75.9 | |||||||||

| Total Mass(kg) | 1.75 | 1.506 | |||||||||

| With Brake | SWG Input Side Inertia(g∙mm²) | 147025 | 110213 | ||||||||

| SWG Input Side Mass(kg) | 0.43 | 0.292 | |||||||||

| OD * Length(mm) | Φ90x98.9 | Φ90x75.9 | |||||||||

| Total Mass(kg) | 1.87 | 1.639 | |||||||||

| Common parameters | ID:18mm, IP grating:IP54, Brake model:friction brake | ||||||||||

| Optional device | Communication type:EtherCAT/CANopen/Modbus; Output encoder resolution:19Bit,Repeatability/Accuracy:±7/±15 arc seconds or ±10/±25 arc seconds. |

||||||||||

| Please note that the specifications provided above are subject to slight variations in different product versions,for precise and specific specifications,it is recommended to refer to the detailed drawings of each model and version;Furthermore,for detailed information regarding accuracy,please consult the following link:https://www.zeroerr.com/about_us/certificates-patents/test-report. | |||||||||||

*

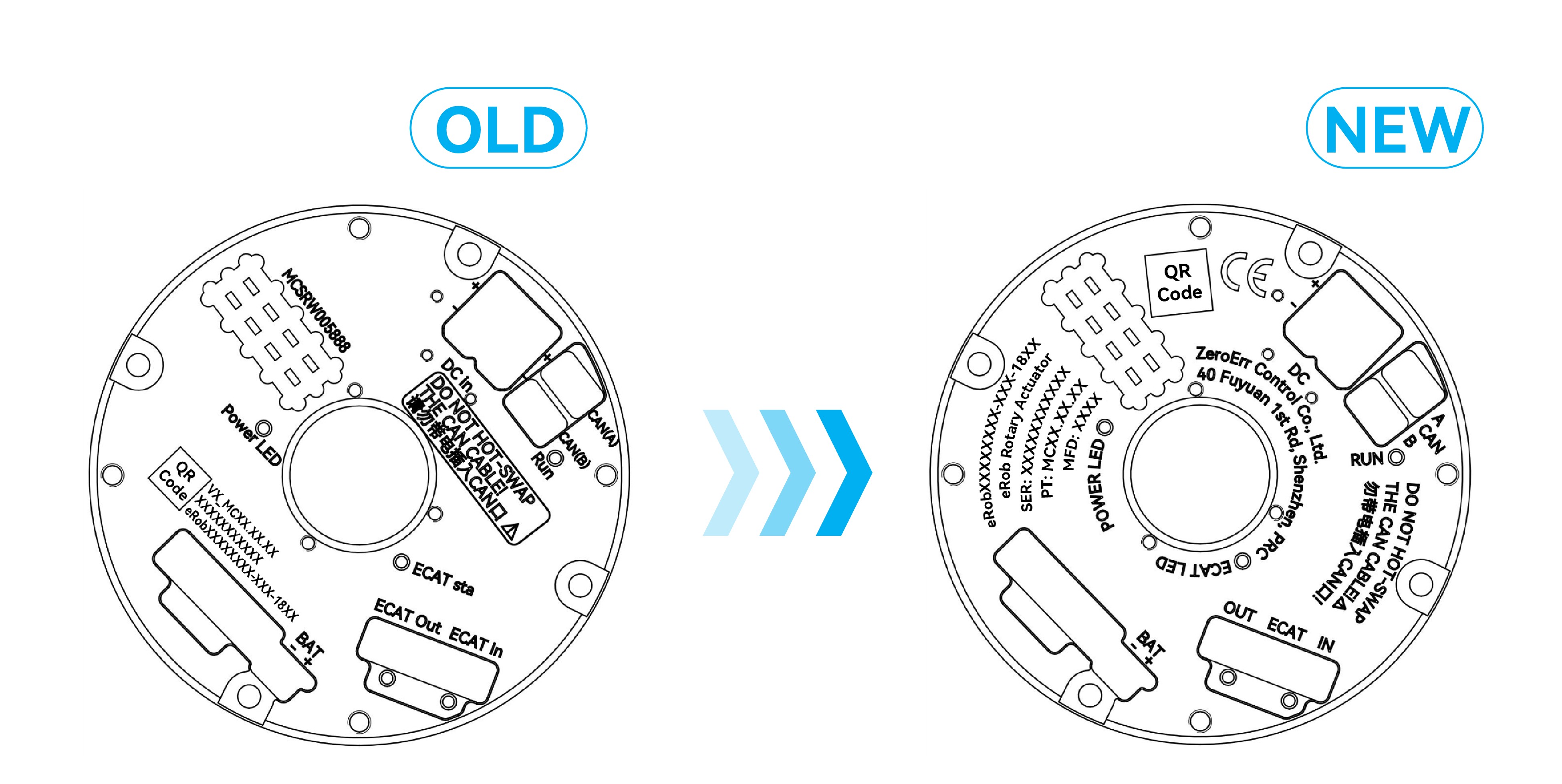

The 'E' in 'MC XX.EX.XX'represents the new version of the back cover.

**

The transition between the old and new versions will occur naturally, with the old version back covers being phased out as inventory is depleted, and the new version back covers being adopted exclusively.

With EtherCAT, CANopen, Modbus communication protocols.

Position,Speed, Current loop PID adjustable in real-time.

Built-in ± 10V analog input.

Pulse and direction, I/O, RS485,

External encoder and STO interface,

All in the space of DxL=70x67mm

19bit absolute multiturn encoder for output shaft.

Repeatability up to ±7 arc seconds.

Absolute accuracy up to ±15 * arc seconds.

Always have real absolute position and multi-turn counter when power-off.

Brake smooth and stable.

No gap; No backlash.

No need to move when power-on.

No wear and tear.

Can be used as Emergency Stop.

Products

Software

Certificates